Simcenter 3D

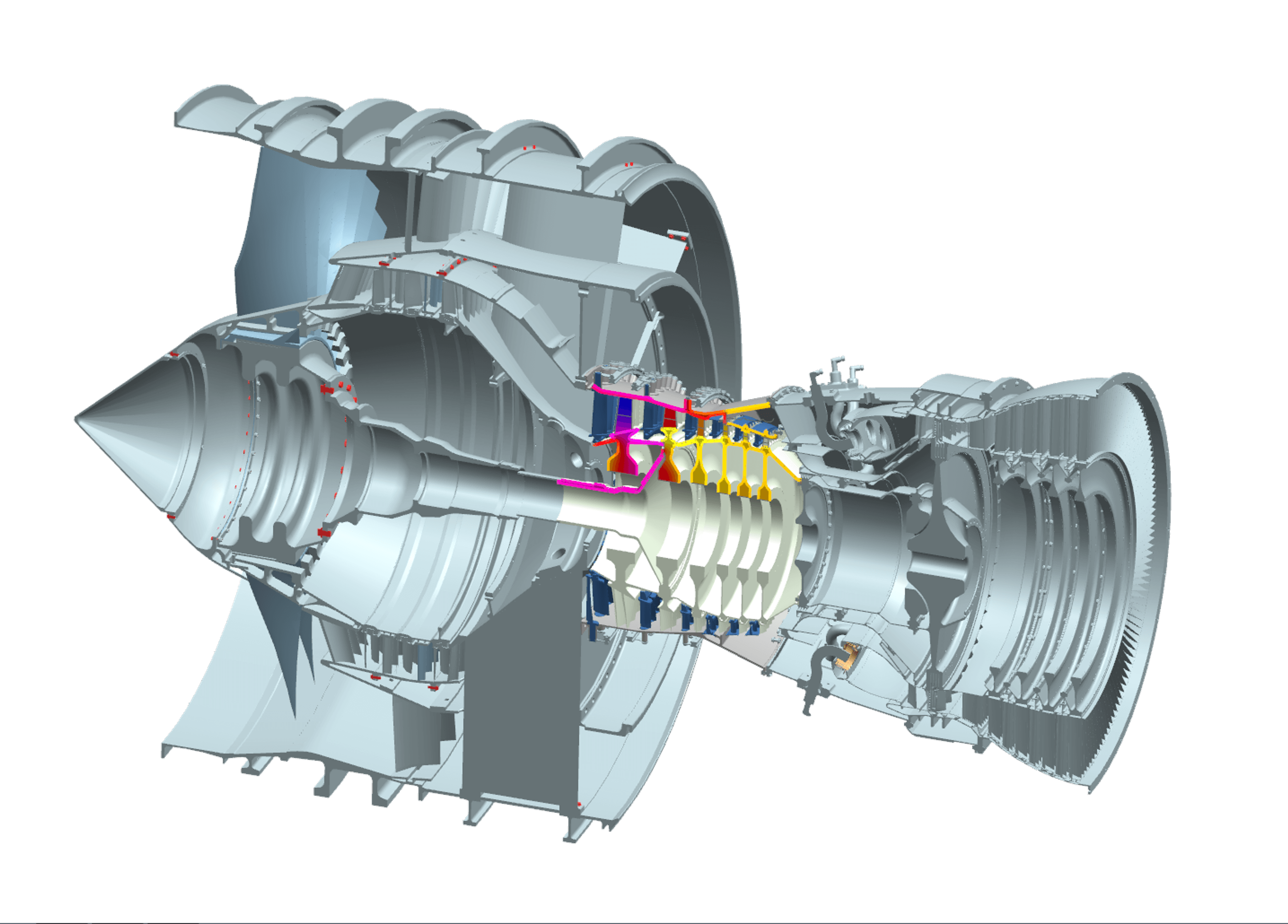

The utilization of new materials and production techniques is transforming contemporary manufacturing processes. Utilizing Simcenter 3D to integrate simulation at the initial stages of the design process ensures precise design analysis, resulting in the production of superior products at an accelerated pace. It addresses aero structure margin of safety analysis, transmission simulation, and fluid-structure interaction, along with additive manufacturing simulation tools.

Benefits include:

• Streamline the prediction of product performance

• Reduce costs and effort

• Expedited simulation process

related products

Achieve accelerated ROI for your business through the implementation of top-tier digital software solutions for Design, Analysis, Manufacturing, Simulation, Data and Lifecycle Management.

Ready to improve your ROI?

Join a Geometric Solutions engineer for a live demo of any of our industry-leading software solutions.

Tap into our proven processes

Learn how Geometric Solutions can help you achieve the exceptional with our engineering solutions.