Do You Actually Know How Good Your Parts Are Today- Right Now?

You manage a single plant, or multiple plants worldwide. You think you are making parts that meet part print tolerances, but how do you really know? If parts are out of specification, how much are they our of spec and does anyone know about it?

Most facilities have multiple measurement systems and quality results are stored in multiple locations. Would it be beneficial to you and your company to have access to all of this information? Imagine being able to see how well the parts made in the last 24 hours from your plant located in Asia are compared to the parts made in the European plant or the North American plant.

Would you think there is value to notify a tool maintenance worker or line foreman via text or email if a part is getting close to falling out of specification? What about notifying the plant manager if the part goes out of spec and has not been fixed within the last 24 hours.

Siemens Dimensional Planning and Validation (DPV) can help. No matter what product you manufacture, DPV can provide your operators, engineers, quality team, and managers with detailed, real-time SPC data, analytics, and reporting they need to assess current processes. Through DPV, your team can take a proactive approach to maintain or improve product quality, meet production goals, reduce costs around scrap and rework, and comply with OEM or industry standards.

Build Quality

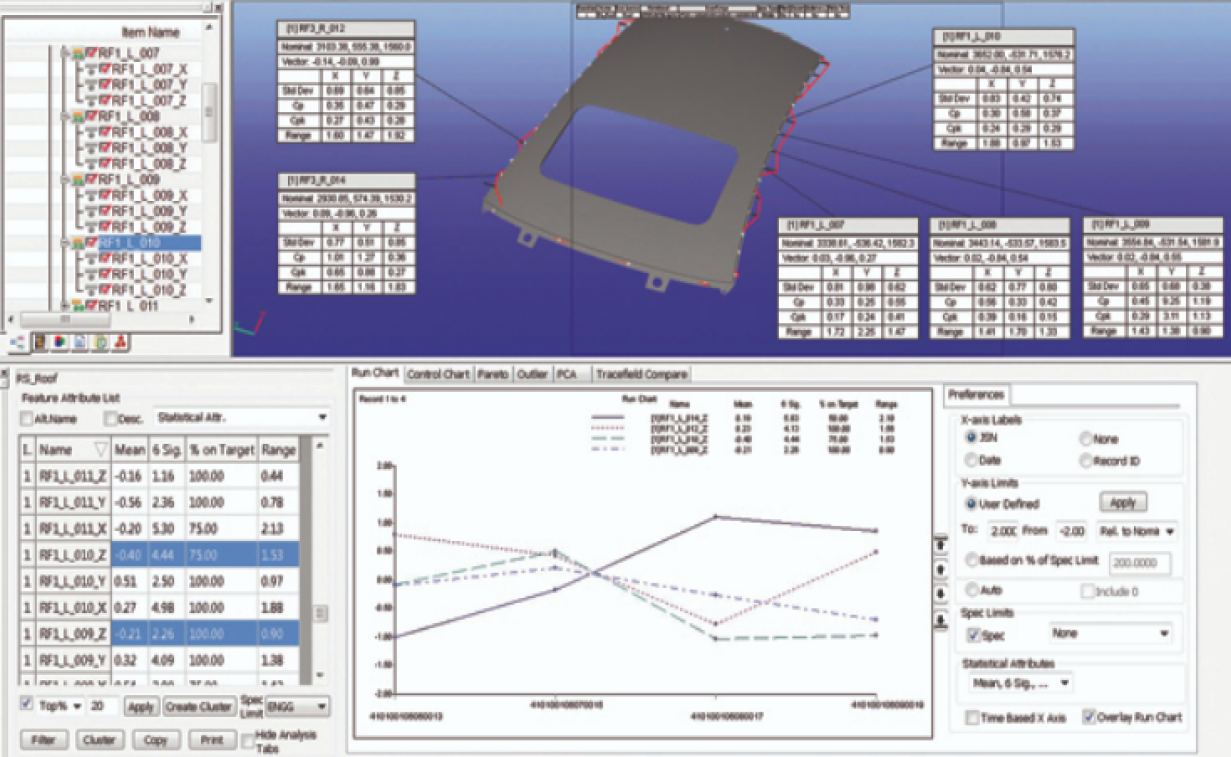

Tecnomatix Dimensional Planning and Validation (DPV) build quality solution helps optimize the throughput of inspection equipment and automate manual processes for data collection, translation, analysis, and reporting. Consolidate the latest inspection results and provide a consistent view of production quality so that your team spends time-solving problems instead of chasing data.

Automate Enterprise-Wide Quality Data Reporting

DPV provides automated report publishing to immediately populate preconfigured report templates with collected quality measurements. You can produce historical summary reports to consolidate extremely large amounts of measurement data, enabling decision-makers to quickly review this information and use it to make metrics-based design and manufacturing choices.

With access to this information, you can compare processes and/or plants, understand process stability, and summarize your company’s performance over any time period.

Integrate Dimensional Measurement Into Planning

DPV helps you plan the process to manage, update, and capture as-designed measurement points and measurement plans in a manufacturing database. Decision-makers can access this data at any time and from anywhere for selected information retrieval.

The definition of your measurement process coordinated with product design, manufacturing planning, and plant layout ensures that the dimensional measurement is integrated into your build quality planning process well in advance of production launch or execution.

Monitor Production for Quality Data Collection

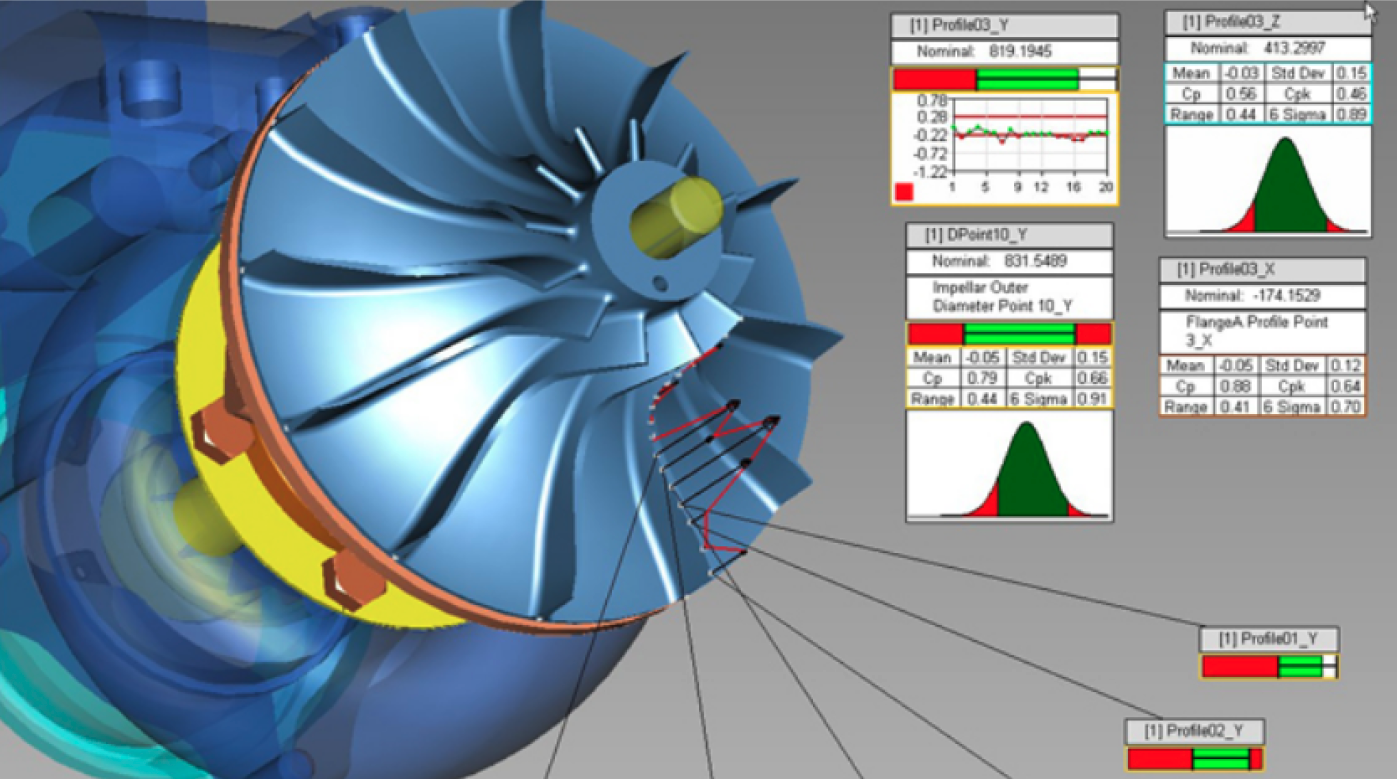

During production, you can monitor and capture measurement data from any device into DPV’s open, flexible architecture. During the loading process, you can use automated tools to proactively identify quality trends.

Siemens' Dimensional Planning and Validation software supports any and all formats and post-processing needs, allowing you to consolidate the quality data collection from all measurement devices in your plant or throughout your enterprise into a single system for a better understanding of build quality.

Perform Statistical, Root-Cause Quality Data Analysis

DPV’s easy-to-use- yet sophisticated statistical techniques -combined with Teamcenter’s 3D geometry capabilities enable your quality teams to rapidly define root causes to build quality issues found in production.

Tecnomatix DPV goes beyond the limitations of fragmented quality solutions and closes the loop between design and production, giving you the ability to directly connect and integrate build quality knowledge into your company’s mainstream product design and manufacturing processes.

To learn how your company can implement Tecnomatix DPV, contact Geometric Solutions- your Siemens Digital Industries software partner.