Using Tecnomatix Manufacturing Simulation solutions you can verify the methods and resources being defined and selected during the manufacturing planning process. The result is proven, right-the-first-time manufacturing plans. With virtual manufacturing process plans simulated digitally, you can validate long before production implementation avoiding costly errors and program slowdowns.

Key benefits include:

- Uncover and resolve changes earlier using simulation

- Reduce or eliminate physical tryouts to shorten startup time for automation systems

- Easily perform engineering studies, including ergonomics and other human factors

Tecnomatix Manufacturing Planning solutions include:

Assembly Simulation and Validation

What if you could virtually simulate and validate your assembly sequences – including all required human and machine interaction? With Tecnomatix Assembly Simulation and Validation, now you can. By optimizing the assembly process virtually, prior to production start-up, ensures you get it right the first time and speeds time to volume production. This capability also reduces tool installation time and minimizes try-out costs.

Tecnomatix Assembly Simulation and Validation includes:

- Process Simulate: a data-managed environment for full detailed assembly operations feasibility and validation tools that allows you to perform sequencing and automatic assembly path planning to simulate your entire process.

Robotics Simulation and Programming

In nearly every industry worldwide, market pressures are forcing today’s manufacturer to build more automation into their production facilities. At the same time, expanding demands for customization and quality complicate automation. Now, more than ever, manufacturers must rely on robotics and automation solutions to boost productivity, efficiency, and flexibility.

Tecnomatix Robotics Simulation and Programming solutions enable you to work in a unified environment that is both managed and file-based. Now you can address a multitude of robot simulation and workstation development – from single robot station to complex production zones – in a virtual environment to optimize performance prior to start-up. These collaborative tools enhance communication and coordination among your manufacturing disciplines to smooth full volume production.

Tecnomatix Robotics Simulation and Programming includes:

- Process Simulate for Robotics and Automation: an events-based robotics and offline programing solution that full integrates with a data-managed environment to help engineers speed automation systems development.

- RobotExpert: this robotics solution provides simulation and offline programming for unique industry-specific applications like material handling, cutting, surface treatment, and arc welding.

- Robcad: a traditional workcell design and simulation tool – on both UNIX and Windows – that enables development, simulation, optimization, validation and offline programming of multi-device robotic and automated manufacturing processes.

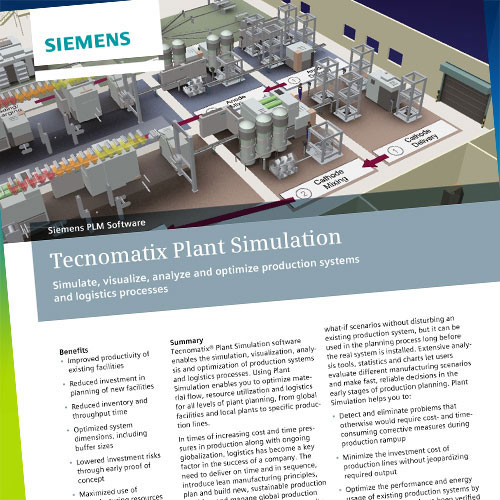

Logistics and Material Flow Simulation

Building products with inefficient manufacturing operations and poor capacity management leads to a rapid decline in your profitability. Tecnomatix Logistics and Material Flow Simulation solutions enable you to manage the myriad of contributing factors that rob productivity and efficiency. For example, determining optimal configuration of new systems, establishing the right level of work-in-progress inventory, setting production schedules, and determining the right production throughput to resource utilization ratio all impact your bottom line. Using discrete event simulation and statistical analysis capabilities, the software can optimize material handling, logistics, machine utilization, and labor needs.

Tecnomatix Logistics and Material Flow Simulation includes:

- Plant Simulation: model, explore, and optimize logistics systems and processes virtually while considering a wide range of manufacturing variables.

- FactoryFLOW: this graphical material handling system allows you to optimize your factory layout based on material flow distances, frequency, and cost to ensure maximum efficiency and cost-effectiveness.

Human Simulation and Ergonomics

Today’s manufacturer needs to address the ergonomic aspect of manual operations during the earliest stages of product and manufacturing development. Worker health and safety are important factors on the factory floor and you need to address them in a cost-effective way. Tecnomatix Human Simulation and Ergonomics solutions you can improve the efficiency, comfort, and safety of your workplace by using human modeling in a virtual environment. You can examine factors like injury risk, timing, user comfort, reachability, line-of-sight, energy expenditure, fatigue limits, and other factors over design and operational parameters. By using virtual simulation, you avoid discovering key human performance and safety issues during production.

Tecnomatix Simulation and Ergonomics includes:

- Jack is a human simulation tool used to populate your design with virtual people performing human operational tasks to simulate, test, improve and refine products and manufacturing tasks.

- Process Simulate Human enables development and verification of process plans in a managed, shared virtual environment across disciplines.