Managing changes in production facilities is one of the most critical phases of a product launch. Tecnomatix Manufacturing Production solutions enable you to commission automated systems, integrate quality monitoring and management, connect shop floor systems and drive continuous improvement programs.

With Tecnomatix Manufacturing Production, you can get products to market faster by reducing system commissioning times, speeding compliance through increased issue visibility, and fix errors faster and earlier to ensure quality.

Tecnomatix Manufacturing Production solutions include:

Issue Tracking and Management

To gain a competitive advantage manufacturers face the challenge of improving product quality while reducing both product and operating costs. Tecnomatix issue tracking and management solutions help achieve these goals with closed-loop issue resolution on a scalable enterprise foundation. With these solutions, you can identify, analyze, and share key product quality date throughout across disciplines throughout your enterprise.

Tecnomatix Issue Tracking and Management solutions include:

Issue Management and CAPA: Corrective Action and Prevention software provides issue management and resolution to identify, analyze, and share product quality among your design, manufacturing and quality improvement teams using a common framework.

Virtual Commissioning

The factory of today is controlled by programmable logic controller (PLC) systems that include sophisticated tooling, robotics, and transfer lines as well as associated safety equipment. Tecnomatix Virtual Commissioning solutions enable you to debug PLC codes in a virtual environment before downloading them to your production equipment. This significantly reduces startup time, and ensures proper and efficient operation at program launch.

Tecnomatix Virtual Commissioning solutions include:

Process Simulate for Robotics: design and validate manufacturing process in a dynamic 3D virtual environment for a wide range of robotic and automation processes.

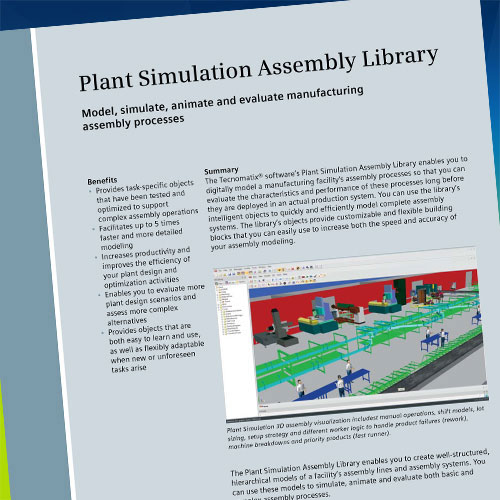

Plant Simulation: debug and simulate PLC codes to optimize your material handling systems such as conveyers, overhead hangers, and transfer lines using discrete-event simulation in a virtual environment.

Shop Floor Integration

To launch new programs efficiently and operate at peak performance, your enterprise needs two-way communication from top floor to shop floor. With Tecnomatix Shop Floor Integration solutions your PLM and your shop floor operations are united through communication of manufacturing work instructions to factory control systems such as manufacturing execution systems (MES). The result? Increased execution efficiency by ensuring the latest work plans are easily accessible on the shop floor – improving alignment between planning and production functions.

Tecnomatix Shop Floor Integration solutions include:

PLM-MES: link product requirements, design, and manufacturing information between your product lifecycle management (PLM) system and your manufacturing execution (MES) system.

Build Quality

Whether you are a multi-national OEM or a smaller single-part manufacturer, assuring build quality throughout the assembly process is critical to success. Using Tecnomatix Build Quality solutions, you can automate data collection, translation, analysis and reporting across multiple machines and methods for viewing in a single user interface. These tools eliminate the need for manual intervention and improve visibility throughout your enterprise.

Tecnomatix Build Quality tools includes:

Dimensional Planning and Validation: Tools for collection, storage, management, reporting, and analysis of measured quality data into a single source of knowledge available across your enterprise.