Tecnomatix planning and management solutions help achieve concurrent engineering by aligning product development with manufacturing process planning. The solution provides collaboration and analysis tools to plan manufacturing digitally – simulating and validating manufacturing processes avoiding production stoppages due to design flaws.

Key benefits include:

- Reduced product launch time due to concurrent product design and manufacturing engineering processes

- Reduced opportunities for error in communicating manufacturing information to the shop floor

- Streamline start-up as plant layout can be planned and optimized digitally in advance of production

- Avoid quality concerns by integrating quality parameters as part of the planning process

Tecnomatix Manufacturing Planning solutions include:

Process Design and Management

With Tecnomatix Process Design and Management, you can get more high-quality products – with more customized options – to market more quickly. The need for speed in deploying new products has driven manufacturers to spread production across multiple plants and suppliers. This movement demands a solution that can align engineering bills of materials (eBOMs), manufacturing bills of materials (mBOMs), and bills of process (BOPs) into a single environment. Tecnomatix Process Design and Management is that environment.

With Tecnomatix Process Design and Management, design and manufacturing engineers to simultaneously develop product and process planning definitions to ensure manufacturing constraints are considered during the design process.

Tecnomatix Process Design and Management includes:

- Manufacturing Process Planner: enables design and manufacturing engineers to develop product and manufacturing process definitions.

- Advanced Assembly Planning: allows manufacturing engineers to configure product and plan BOPs independently.

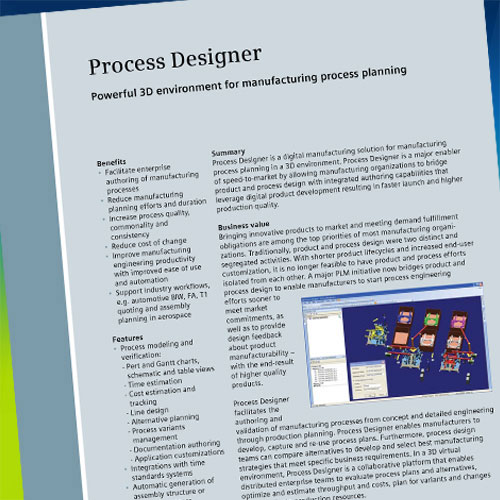

- Process Designer: bridges the gap between product and process design functions to accelerate process design efforts by starting earlier in the cycle.

Manufacturing Work Instructions

Step-by-step work instructions detailing part fabrication through the final assembly process has been necessary since the beginning of mass production. But it remains a challenge for most manufacturers to get the most current work instructions to the point of manufacture efficiently and with accuracy. Add in global production with multiple sites, numerous product variants, and changing production set-ups and you have the even greater complexity.

Tecnomatix Work Instructions provides an integrated environment that unites product, process, resource, and plant information into a single, managed environment. Harnessing Teamcenter’s configuration capabilities, now process documentation can be automatically updated to enable you to react to changes responsively.

Tecnomatix Manufacturing Work Instructions includes:

- Electronic Work Instructions: gives shop-floor workers access to 3D animated work instructions directly from the Teamcenter source file.

- 3D Documents: gives shop-floor workers access to 3D animated work instructions directly from the Teamcenter source file.

Factory Design and Optimization

Now you can digitally design, layout, configure and optimize your factory environment with Tecnomatix Factory Design and Optimization. These 3D virtual models allow you to optimize factory layouts and account for factors like clearance, energy, noise, and safety considerations. With this virtual capability, your design teams will have the ability to see the impacts of their decisions in virtual facilities – avoiding costly re-configuration and wasted resources

Tecnomatix Factory Design and Optimization includes:

- FactoryCAD: create detailed intelligent factory models in this 3D layout applications using “smart objects” that represent factory resources.

- FactoryFLOW: this unique graphical material handling system enables you to optimize plant layouts based on material flow distances, frequencies, and associated costs.

- In Context Editor (ICE): Easily access 2D and 3D FactoryCAD data to collaboratively manage factory layout data and maintaining the layout plan in the context of the manufacturing BOP.

Dimensional Quality

With Tecnomatix Dimensional Quality solution, you can analyze the impact of manufacturing processes on design features and tolerances before they reach the shop floor. This capability helps you avoid the high cost of hunting down and fixing product quality issues during production. Tecnomatix Dimensional Quality improves design quality and reduce or eliminate costly prototypes – all while reducing labor, tooling, and metrology costs.

Tecnomatix Dimensional Quality includes:

- Variation Analysis: a powerful tool which can simulate manufacturing and assembly processes to identify the amount and root causes of dimensional variation prior to production