NX

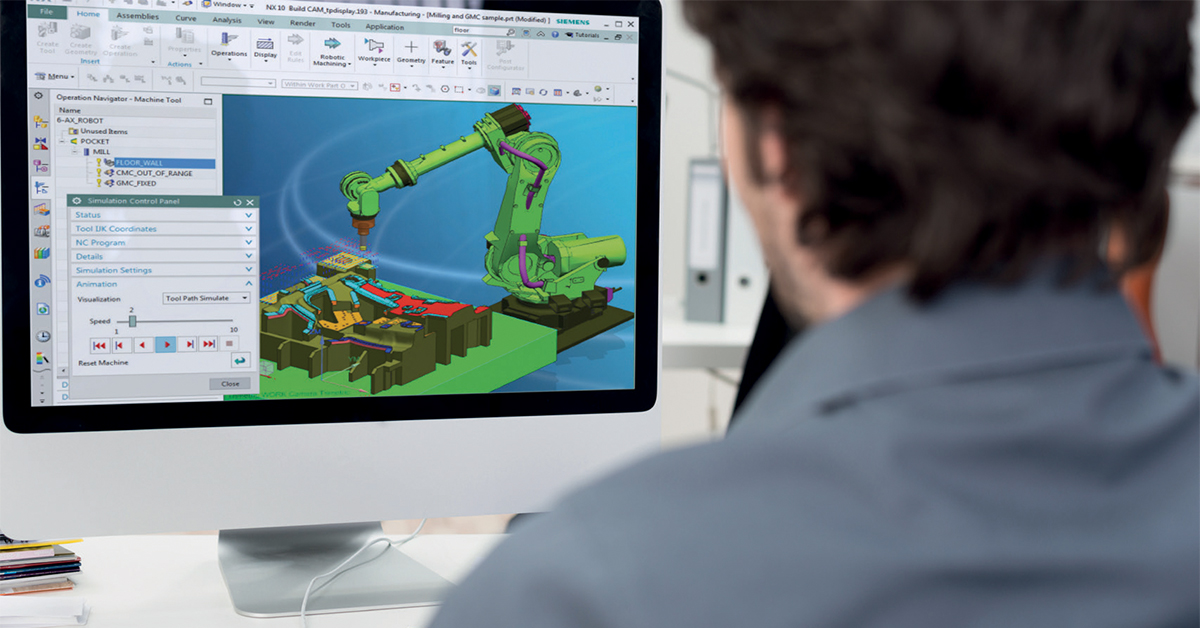

Siemens NX software is a flexible and powerful integrated solution that helps you deliver better products faster and more efficiently.

NX delivers the next generation of design, simulation, and manufacturing solutions that enable companies to realize the value of the digital twin. Supporting every aspect of product development, from concept design through engineering and manufacturing, NX gives you an integrated toolset that coordinates disciplines, preserves data integrity and design intent, and streamlines the entire process.