Changing the Shape of Design

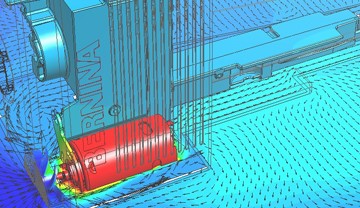

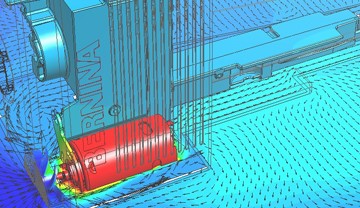

By starting simulation early in design, changes are made when they are easiest, time-to-manufacture is shortened, and cost-to-manufacture can be reduced. And accurate simulation of complete models reduce the number of physical prototypes and further reduce time and cost.

Continue Reading

Take your innovation to the next level

Do you feel like you’re fighting a never-ending battle to get innovative new products to market faster than ever before? The pace of innovation is a key success factor in today’s competitive landscape. The next generation of products will require a next generation design solution to create and deliver them. That solution is available today.

Continue Reading

Engineering and design companies are racing to be first to market with products. In order to meet this goal, engineers and designer are first looking to tools that allow them to accelerate their design development process. The CAD tool, used to create 3D designs, is the first obvious place to look for enhancements. But there are problems, here.

The traditional tools of 3D design rely heavily on design concepts and limitation of hardware from over two decades ago.

Design groups using traditional history-based CAD tools are finding that their design process has plateaued. It is getting harder and harder to squeeze time out of the design development process to make it to the next level. What are design groups to do?

Continue Reading

Many industries use scanned 3D data as part of their design processes. Prior to Convergent Modeling, to work with the scanned data, the user would have to re-create the scanned design using surfaces and solids ― using the facets as a reference only. This is a time-consuming and exacting process - requiring significant time and skill.

With Convergent Modeling in NX Design Software, this process is easier than ever before because the same modeling techniques and features you use to create native CAD geometry can now be used on facet geometry.

Continue Reading