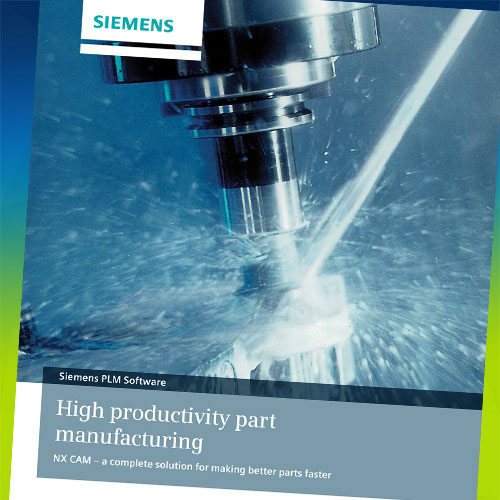

Machinery Part Programming in NX CAM

A Comprehensive Part Programming Solution for Industrial Machinery and Heavy Equipment

Specific NC part programming needs for industrial machinery and heavy equipment are supported by NX CAM.

By combining familiar CAD/CAM, programming automation, and integrated machine tool simulation capabilities with automated, context-specific functions, NX CAM becomes your machining solution for simplifying the creation of smart tool paths for prismatic parts quickly and accurately.

Volume-Based 2.5D Milling

Program prismatic parts quickly as NX previews and specifies the sequence of volumes to be machined.

View the current in-process workpiece (IPW) with the help of the volume-based 2.5D milling processor. Then use it to select the defining faces of a machining volume – floors, walls, check surfaces and stock surfaces – and see the calculated cut levels and the updated IPW.

Multi-Stage Machining

The multi-stage IPW capabilities enhance milling, turning, and mill-turn functions. A stock-sensitive programming capability automatically tracks uncut volumes across multiple setups, thus simplifying the programming process. Tool paths remain safe and air cuts are eliminated as an instant preview displays uncut volumes for each setup.

Full Range of CAD/CAM Capabilities for Machinery Parts

The full range of CAD/CAM capabilities NX delivers – in addition to optimized operations for machinery part programming – includes:

- Advanced NC programming for milling, drilling, turning, mill-turn and wire EDM machines

- Feature-based machining (FBM) lets you drastically reduce part programming time

- Integrated machine tool simulation verifies programs

- Synchronous technology lets you quickly repair imported models

- CAD capabilities help you design fixtures and document setups