Digital manufacturing for tomorrow’s factory, today.

Tecnomatix® software is designed to empower manufacturers to digitalize manufacturing and the process of turning their innovative product ideas and raw materials into transformative products. The latest Tecnomatix® release continues to deliver the advanced digital manufacturing capabilities that you have come to expect.

With Tecnomatix® software, you achieve synchronization between product engineering, manufacturing engineering, production, and service operations to maximize your production efficiency. The Tecnomatix® portfolio provides manufacturers with the kinds of new and innovative capabilities that effectuate processes of specific industries, and suggest enhanced solutions that are designed to optimize factory layout, robotic utilizations, and human simulations, while –at the same time– improving the overall user experience.

Enhanced benefits and features:

The latest release of Tecnomatix® delivers enhancements for simulation, path authoring and offline programming (OLP), including improved debugging tools and out-of-the-box support for robot program creation and simulation.

Improved methods and capabilities to create virtual commissioning simulations, enhanced behavior modeling via internal and external tools, and Virtual Robot Controller integration for commissioning are also available.

Industry-focused solutions especially designed for Automotive & Transportation, Aerospace & Defense, Heavy Equipment Machinery, Consumer Packaged Goods, and Electronics & Semiconductor industry users. Innovative capabilities designed to optimize digital factory layout, robotics utilizations, human simulations, and more. Explore the features of our latest release.

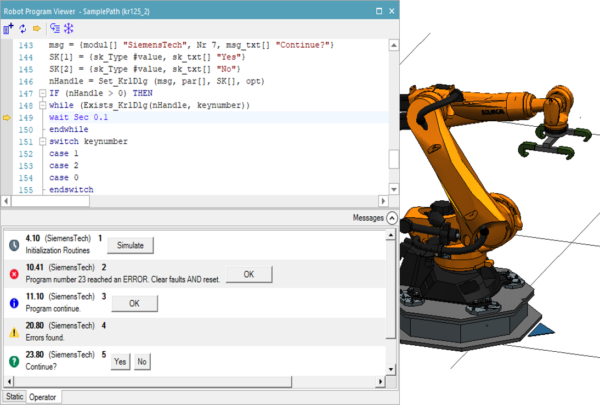

Robot operator messaging for Kuka robots

Interact with Kuka Robot Programs using the Robot Program Viewer’s new Operator messaging panel. The new panel displays operator messages for Kuka robots created by OLP commands, such as MsgNotify, and allows you to interact with the robot by viewing messages and selecting actions using configured buttons. The Process Simulate Kuka KRC Controller (version 4.15 or higher) has been extended to support Kuka’s standard MsgLib.src file without any customization, allowing you to easily display operator messages in the Robot Program Viewer.

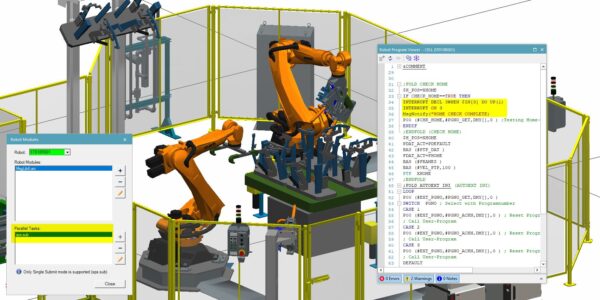

Robot parallel tasks – Kuka submit interpreter

Simulate single submit interpreter and global variables commands for Kuka Robots. The KRC controller also accepts additional syntax in OLP commands such as the “WAIT FOR” function, allowing for easier virtual commissioning using the out-of-the-box KRC Controller, with less need for customization.

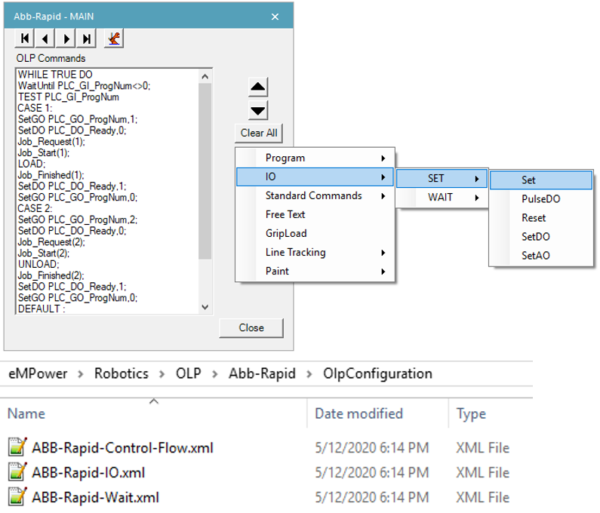

Improved offline programming using ABB Rapid

Access out-of-the-box custom XML files for the ABB Rapid controller. These XML files serve the dual purpose of delivering an improved user experience to ABB Rapid programmers in Process Simulate and providing examples of how to author custom program XML code. The supplied XML files provide a user interface for commands already supported by the simulation including Set, Wait and other commands.

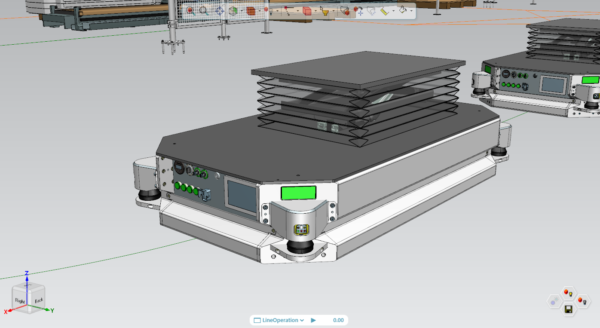

Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR)

Process Simulate supports event-based simulation of AGVs and AMRs in the manufacturing environment and enables validation and virtual commissioning of all production and logistics aspects for AGV systems.

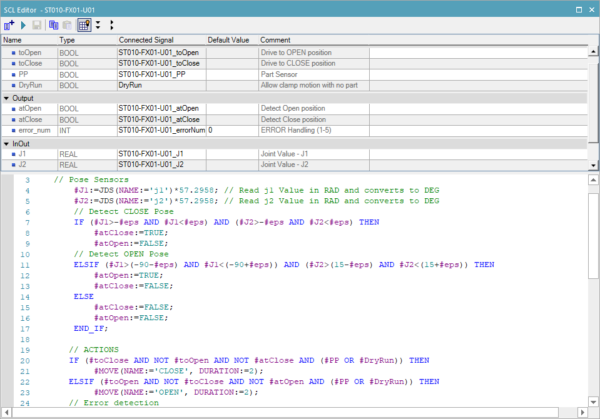

Structured Control Language (SCL) editor

The SCL Editor is a new tool for building logical behavior for resources (i.e., Smart Components). Like the Logic Block (LB), SCL allows adding and editing the logic of a resource prototype, but with an interface that is easier to use and a worldwide, commonly practiced programming language. It allows improved capabilities such as bit access inside a byte, assignment of default variable values per resource instance, easy copying between different resources, editing multiple SCL Blocks in parallel, easy programming using function calls, auto complete, and more.

Process Simulate includes a library for telegram behavior models based on SCL. This allows virtual commissioning users to control Siemens drives using behavior models for telegrams included directly inside Process Simulate.

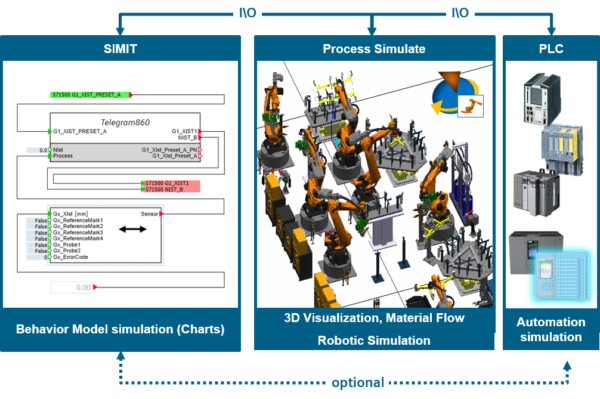

SIMIT external connection

The updated SIMIT external connection allows users to directly couple their Process Simulate cell with its robot programs, material flow, layout, and kinematic definitions to a SIMIT project. The SIMIT project can include logical behavior models and additional PLC connections (couplings) using a simple name-based I/O exchange, allowing easier virtual commissioning for users of both SIMIT (v10.2) and Process Simulate (v16.0).

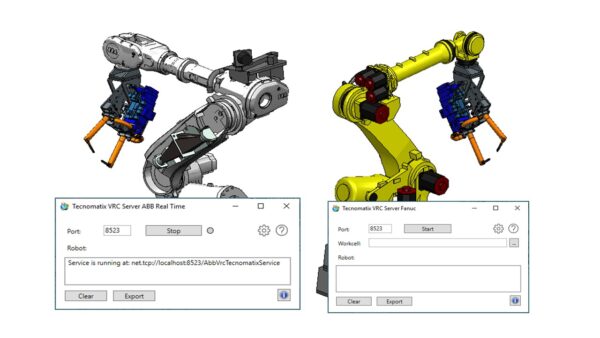

Virtual Robot Controller (VRC) simulation

VRC connections allow users to connect to ABB’s RobotStudio or Fanuc’s ROBOGUIDE in order to simulate complete robot systems using the robot vendor’s tools in conjunction with Process Simulate’s complete environment for highly accurate virtual commissioning with minimal setup effort taken directly from any actual robot. When in VRC mode, robot programs are executed by the VRC and are visualized in Process Simulate. Process Simulate exchanges signal information (I/O) with the VRC and facilitates communication between robots, peripheral devices, and PLCs.

Human Factors and Ergonomics

Tecnomatix® allows you to quickly author task simulations using predictive technologies, automatically generate comprehensive ergonomic reports, use the motion capture and tracking system to animate human work with your own motions and analyze them in real-time – all with new human figures!

Next generation human figures

With Tecnomatix®, we introduce the new human figures! Many years in the making, these next generation avatars are the most advanced available. Fully textured for exceptional visual appeal, matched with state-of-the-art anthropometric scaling that provides bodyscan level shape fidelity, these figures take human modeling to the next level of visual and dimensional realism.

The figures feature efficient new meshes along with skin, clothing, face and hair textures. Shirt, pants, hair, shoes and even eye color can be easily modified for a unique figure look.

Metabolic energy expenditure analysis

With Process Simulate Human, the Metabolic Energy Expenditure (MEE) analysis has been integrated with the Task Simulation Builder (TSB) system. You can now easily create a comprehensive energy expenditure analysis of a TSB task sequence, quickly assessing risk of fatigue. Based on the Garg expenditure equations, the analysis allows you to identify the most demanding activities in the sequence, providing guidance on how best to reduce maximum metabolic cost demands.

Virtual Reality (VR)

Tecnomatix® helps you become immersed in your production line. Use the VR environment for better engineering reviews, staff training and realistic process validation, finding issues faster, and identifying optimization opportunities while collaborating with other teams and your customers.

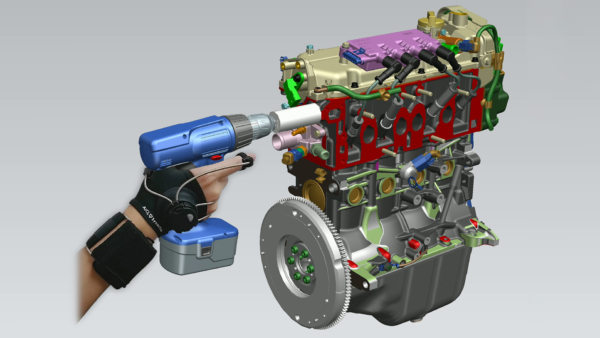

Live hands

Using motion capture glove hardware and Process Simulate VR hand figures, you can explore reachability, clearance and object manipulation in the Process Simulate VR immersive environment. You can use gestures and function keys to grasp, pick up and release objects such as tools and parts while immersed.

Point clouds

With this release, you can load a Process Simulate study containing point cloud data into an immersive VR session. You can customize the point cloud to reduce the number of points that are loaded into VR for improved performance.

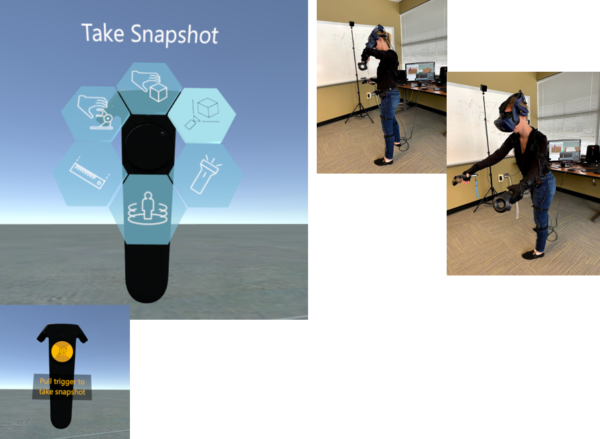

Snapshots

Exploring virtual environments with Virtual Reality and Process Simulate Human motion tracking can help identify reachability, clearance, vision and other human factors issues. Often, the postures experienced during an immersive session can be of significant value afterwards, both for issue communication as well as for in-depth ergonomic analysis.

With the “Take Snapshot” feature, Process Simulate Snapshots can be captured at any time while immersed, allowing postures of interest to be saved for later use. Snapshots are captured from the viewpoint of the HTC Vive headset and the visual scene flash gives feedback of the snapshot capture.

Make a Note

While immersed in VR, you now can document issues with several types of notes and icons. Each note carries a picture taken in VR to best describe the issue found. The notes icons are seen in the Process Simulate graphics in the same position in space, allowing you to easily understand the current maturity status of each area following the review session. Follow up on each note in Process Simulate or virtual reality to view related pictures, add comments or change its status as the issue is brought to resolution.

Interested in learning more how the Tecnomatix® suite of software will help you maximize your production efficiency? Contact us today.